Understanding Multi-Layer Rubber Membrane Technology

The realm of multi-layer rubber membrane technology is paving the way for innovative solutions across various sectors, particularly in the areas of Health & Medical, Beauty & Spas, and Medical Spas. These versatile membranes are engineered to deliver exceptional performance, durability, and flexibility, making them a staple in modern applications.

What is a Multi-Layer Rubber Membrane?

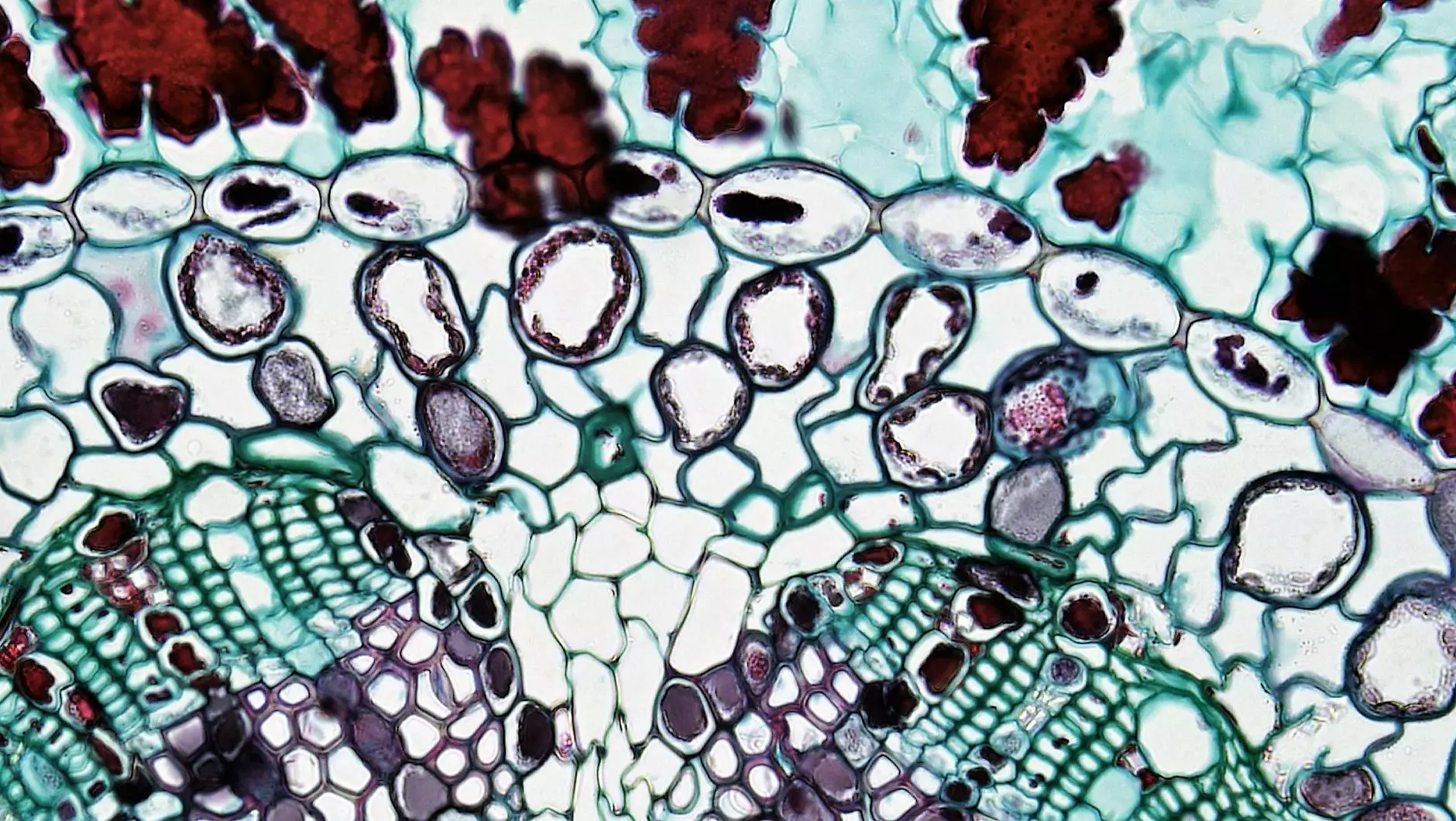

A multi-layer rubber membrane is an advanced material composed of various bonded layers of rubber and synthetic elastomers. This structure is meticulously designed to enhance the material's strength, flexibility, and resistance to environmental influences. The layered structure allows for tailored properties such as increased durability, better waterproofing, and superior resistance to chemicals and UV radiation.

The Composition of Multi-Layer Rubber Membranes

Multi-layer rubber membranes often consist of several types of materials, including:

- Natural Rubber: Offers excellent elasticity and tensile strength.

- Synthetic Rubber: Such as EPDM and SBR, providing enhanced weather resistance.

- Polymer Coatings: To enhance durability and longevity.

- Adhesives: Used to bond the layers together for optimal performance.

Applications of Multi-Layer Rubber Membranes

The applications of multi-layer rubber membranes are vast and varied, ranging from industrial to everyday uses. Here are some primary applications:

1. Health & Medical

In the health and medical industry, multi-layer rubber membranes are critical for various applications:

- Medical Devices: Utilized in the manufacture of seals and gaskets for medical devices, ensuring they are sterile and waterproof.

- Protective Gear: Used in the production of personal protective equipment (PPE) to protect against biological hazards.

- Medical Spas: Found in treatments involving water therapy or detox procedures where moisture resistance is paramount.

2. Beauty & Spa Treatments

In the beauty and spas industry, multi-layer rubber membranes are increasingly used in:

- Hydrotherapy Equipment: Essential for creating waterproof and durable components in devices that provide hydrotherapy treatments.

- Prototype Development: Assist in the development of new beauty devices that require water or moisture interaction.

3. Construction and Infrastructure

From roofs to foundations, multi-layer rubber membranes provide unparalleled waterproofing solutions:

- Roofing Systems: Used for protecting roofs from leaks, ensuring long-lasting durability.

- Waterproofing Foundations: Essential for building structures that are resilient against moisture ingress.

Benefits of Multi-Layer Rubber Membranes

The effectiveness of multi-layer rubber membranes in various applications can be attributed to their numerous benefits, including:

- Durability: The layered nature enhances wear and tear resistance, extending the lifespan.

- Flexibility: Adapts to various forms and shapes without losing integrity.

- Customization: Can be engineered to meet specific needs for different industries.

- Environmental Resistance: Resistant to extreme temperatures, UV radiation, and chemical exposures.

- Cost-Effectiveness: Reduced maintenance and replacement costs due to durability.

Comparing Multi-Layer Rubber Membranes with Other Materials

When evaluating materials for specific applications, it's crucial to compare multi-layer rubber membranes with other types of membranes and coatings:

1. Single Layer Membranes

Single layer membranes may be less costly, but they often lack the durability and environmental resistance found in multi-layer structures. They are more susceptible to tearing and less effective at sealing against moisture.

2. Other Composite Membranes

Although other composite membranes might offer certain advantages, they typically do not provide the same level of flexibility or customizability as multi-layer rubber membranes, making these superior for applications requiring specific performance metrics.

Environmental Impact and Sustainability

The production and disposal of materials have significant environmental implications. Multi-layer rubber membranes can be designed with sustainability in mind:

- Recyclable Materials: Selecting recyclable components can mitigate environmental impact.

- Energy-Efficient Production: Utilizing manufacturing processes that consume less energy can contribute to overall sustainability.

- Long Lifespan: The durability of multi-layer rubber membranes means they need to be replaced less often, reducing waste.

The Future of Multi-Layer Rubber Membrane Technology

As advancements continue in material science and technology, the future of multi-layer rubber membranes looks exceedingly promising. Innovations may include:

- Smart Membranes: Integrating sensors to create responsive materials that adapt based on environmental changes.

- Enhanced Customization: The ability to produce membranes tailored for highly specialized applications.

- Green Innovations: Further development of eco-friendly materials that do not compromise performance.

Conclusion

In summary, multi-layer rubber membranes represent a revolutionary step forward in technology with applications that span numerous industries, particularly those in Health & Medical, Beauty & Spas, and Medical Spas. Their unique properties offer a combination of durability, flexibility, and environmental resistance that make them indispensable in today's ever-evolving market.

As businesses and manufacturers continue to seek innovative solutions to meet modern challenges, the adoption and development of multi-layer rubber membranes will undoubtedly play a critical role. The future is bright for this technology, promising advancements that will lead to even greater applications and benefits across various sectors.

For businesses interested in exploring the potential of multi-layer rubber membranes, particularly in the domains of silicone solutions, silicone-membranes.eu provides a wealth of information and resources to guide decisions and foster innovations.