OEM China High Speed Cutting Wheels: Revolutionizing Cutting Solutions

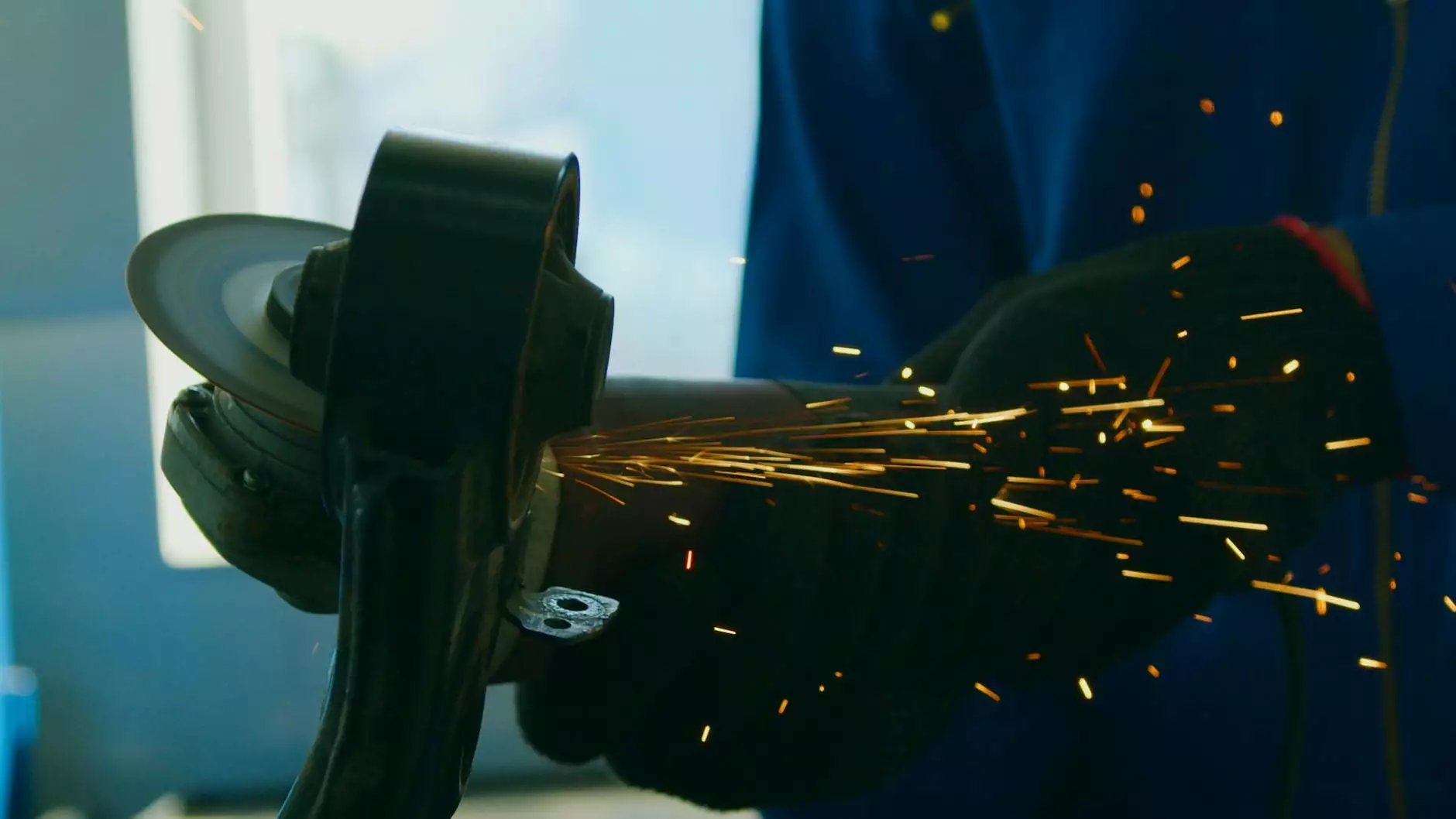

The need for high-quality cutting tools has never been more crucial in today’s fast-paced manufacturing and industrial landscape. Among the plethora of options available, the OEM China high speed cutting wheel stands out as a fundamental component that drives efficiency and precision in cutting tasks across various sectors. In this extensive article, we delve deep into the characteristics, benefits, and applications of these cutting tools, providing manufacturers and industrial users with comprehensive insights.

Understanding OEM China High Speed Cutting Wheels

OEM, or Original Equipment Manufacturer, pertains to companies that produce components or products that are used in another company's end product. In the realm of cutting tools, this means that OEM manufacturers in China are producing cutting wheels that meet international standards while providing superior performance. High speed cutting wheels are designed to handle various materials, including metals, plastics, and composites, making them invaluable in numerous industries.

Key Characteristics of High Speed Cutting Wheels

When it comes to selecting cutting wheels, understanding their key characteristics is essential. Here are some pivotal attributes of OEM China high speed cutting wheels:

- Manufacturing Standards: These cutting wheels are produced under stringent quality control measures that comply with international standards, ensuring durability and safety.

- Material Composition: Made from premium materials such as aluminum oxide, silicon carbide, or diamond, providing the necessary hardness and resistance to abrasion.

- Speed Capacity: Designed to operate effectively at high speeds, thus increasing productivity while reducing the risk of overheating.

- Versatility: Suitable for a wide range of applications, from metal fabrication to construction, ensuring a broad market reach.

Efficiency and Performance

The efficiency of a cutting wheel can dramatically affect the manufacturing output. The OEM China high speed cutting wheel is engineered to optimize cutting speed while maintaining a clean and precise cut. This efficiency translates into lower operating costs, reduced material waste, and increased productivity, making these wheels a valuable investment for businesses.

Why Choose OEM China High Speed Cutting Wheels?

There are several reasons why opting for OEM China high speed cutting wheels makes sense for business owners, contractors, and manufacturers alike:

Cost-Effectiveness

China is known for its robust manufacturing capabilities and competitive pricing. By sourcing high speed cutting wheels from reputable OEM manufacturers, companies can save significantly without compromising quality.

Quality Assurance

Leading OEM manufacturers implement strict quality assurance protocols, often exceeding typical international standards. This guarantees that every cutting wheel performs reliably under various conditions, enhancing both safety and effectiveness.

Customized Solutions

Many OEM suppliers offer tailored solutions that cater specific needs of customers. This means businesses can acquire cutting wheels designed for specialized applications, further increasing their operational efficiency.

Applications of High Speed Cutting Wheels

The versatility of the OEM China high speed cutting wheel makes it suitable for a variety of industries:

- Metal Fabrication: Widely used for cutting steel, aluminum, and other metals with precision.

- Construction: Essential for cutting bricks, tiles, and other building materials.

- Automotive: Utilized for parts manufacturing and repair, focusing on quality and precision.

- Prototyping: Ideal for R&D processes needing custom shapes and sizes in rapid development stages.

How to Choose the Right OEM China High Speed Cutting Wheel

Choosing the right cutting wheel can be a daunting task given the multitude of options available. Here are some essential factors to consider:

Material Specifications

Knowing the material you will be cutting is paramount. The selection of a cutting wheel should align with the material's composition and thickness to achieve optimal results.

Wheel Size and Thickness

The diameter and thickness of the cutting wheel influence its performance. Thicker wheels are generally used for heavy-duty cutting, while thinner wheels offer higher speed and precision.

Speed Rating

Always check the manufacturer's specifications for maximum RPM (Revolutions Per Minute). Using a wheel beyond its rated speed can lead to accidents and reduced tool life.

Application Type

Consider the specific application and the type of cut required. Do you need a straight cut, a curved cut, or something more intricate? Ensure that the cutting wheel matches these requirements.

Maintenance Tips for Longer Life

To ensure the longevity and effectiveness of OEM China high speed cutting wheels, proper maintenance is critical. Here are some practical tips:

- Storage: Store cutting wheels in a cool, dry place to prevent moisture absorption and degradation.

- Inspection: Regularly inspect cutting wheels for any signs of damage or wear. Replace them as necessary.

- Proper Usage: Always use the cutting wheel within its specified limits—both in terms of material and speed—to prevent premature wear or accidents.

- Cleaning: Keep the surface of the cutting wheels clean from debris to maintain cutting efficiency and safety.

Conclusion: Elevate Your Cutting Operations

Investing in OEM China high speed cutting wheels is not merely a choice but a strategic decision that can transform your cutting operations. With unrivaled quality, performance, and versatility, these cutting wheels have the potential to enhance productivity and reduce costs significantly. Whether you’re in construction, manufacturing, or another industry requiring precision cutting tools, opting for these high-speed options is a surefire way to achieve excellence. As you explore suppliers, remember to focus on reputable OEM manufacturers who align with your operational needs and quality expectations.

For more information on superior quality cutting wheels and to view a wide range of options, make sure to visit szblade.com today!